When you walk up to a vending machine for a quick snack or drink, security may be the last thing on your mind. But behind every purchase lies a small yet crucial piece of hardware — the vending machine plunger lock. This simple-looking device serves as the gatekeeper, protecting the machine’s valuable inventory and cash box from unauthorized access.

Plunger locks, sometimes referred to as pin tumbler locks, are one of the most widely used locking mechanisms in commercial environments. Their compact size, reliable operation, and cost-effectiveness have made them a standard choice for securing vending machines, kiosks, cabinets, and other high-traffic equipment.

In this article, we’ll explore exactly what a vending machine plunger lock is, how it works, why it remains relevant in the age of electronic security, and what owners can do to maintain and protect these locks from tampering.

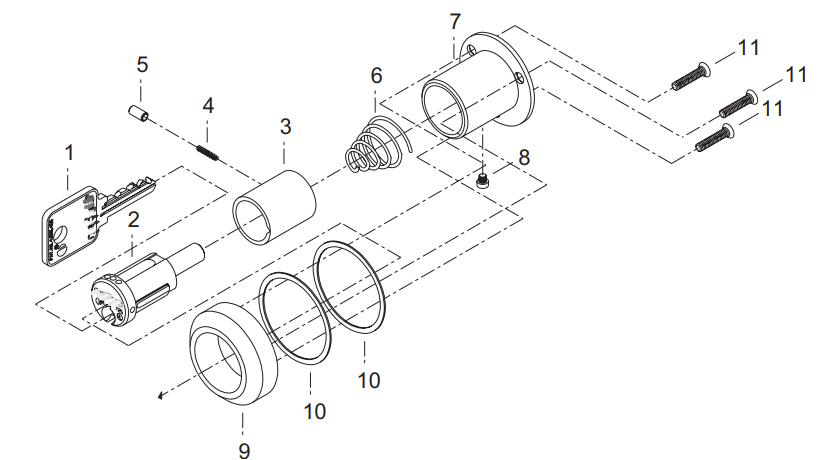

At its core, a plunger lock is a mechanical locking device designed to restrict access unless the correct key is used. The lock contains a cylindrical plug that rotates inside a fixed housing, with a series of spring-loaded pins arranged vertically. The lengths of these pins vary, making it impossible to turn the plug unless each one is positioned at the exact height needed for the shear line to align.

When the proper key is inserted, its grooves lift each pin to the correct position, allowing the plug to rotate and disengage the locking mechanism. This time-tested design offers a good balance between affordability, ease of use, and resistance to basic picking attempts.

In vending machines, the plunger lock is typically located at the machine’s service door or cash compartment, acting as the primary barrier to theft. Many vending operators favor these locks for their straightforward operation and low maintenance requirements.

The operation of a plunger lock may seem almost magical to the casual user — insert the key, twist, and the lock opens. But the process is a precise mechanical dance between the pins, springs, and key profile. Here’s how it works in detail:

Locked State – When the lock is closed, the spring-loaded pins extend partly into both the plug and the housing. This overlap physically prevents the plug from turning.

Key Insertion – The correct key is inserted into the keyway. Each cut or ridge on the key corresponds to a specific pin height inside the lock.

Pin Alignment – As the key slides in, it pushes the lower pins up or down. The correct key will move each pin so that the split between its upper and lower section — known as the shear point — aligns perfectly with the shear line.

Rotation – With all pins aligned, there’s no obstruction between the plug and housing, allowing the plug to rotate freely.

Unlocking Mechanism – Turning the key moves the locking bolt or cam attached to the plug, disengaging it from the vending machine’s latch system.

The genius of the design is that even if one pin is misaligned, the plug won’t turn. This makes random attempts at opening the lock extremely difficult without the correct key.

The vending machine industry faces a unique set of security challenges. These machines often sit in unattended, public spaces where they are exposed to potential tampering or theft.

Key reasons plunger locks are favored include:

They can be integrated into the machine’s surface without adding bulk or attracting attention.

Plunger locks provide solid protection without the expense of advanced electronic systems.

Operators can issue keys to service personnel without needing specialized training.

Built from robust materials such as brass or hardened steel, they can withstand frequent use and environmental exposure.

Available in keyed-alike or keyed-differently configurations, they fit varying operational needs.

While their name may suggest they are solely for vending equipment, plunger locks are versatile and used in multiple industries:

Retail Display Cabinets – To secure merchandise without sacrificing visibility.

ATM Service Doors – Protecting access to cash-loading compartments.

Gaming Machines – Used in slot machines and arcade cabinets.

Office Furniture – Securing drawers and filing cabinets.

Industrial Enclosures – For locking control panels or machinery compartments.

A quality plunger lock must be tough enough to deter forced entry attempts while maintaining smooth operation for authorized users. Typical materials include:

Brass – Resistant to corrosion and offers smooth key action.

Hardened Steel – Provides added resistance to drilling and physical attacks.

Zinc Alloy – Cost-effective yet durable for light- to medium-security needs.

The finish may also be chrome-plated or nickel-plated to improve weather resistance, which is crucial for outdoor vending machines.

Modern plunger locks are far from basic. Manufacturers now integrate advanced features to combat increasingly sophisticated theft methods:

Anti-Pick Pins – Specially shaped pins (such as spool or mushroom pins) that bind when manipulated incorrectly, making lock picking more difficult.

Drill-Resistant Housings – Hardened inserts protect the pin chamber from drilling attacks.

Key Control Systems – Keys can be patented and restricted so they cannot be duplicated without authorization.

High-Security Cams – Reinforced mechanisms to resist prying or torque attacks.

No mechanical lock is completely invulnerable. Plunger locks can be targeted by:

Lock Picking – Skilled attackers may use tension wrenches and picks to manipulate pins.

Drilling – Drilling through the cylinder to destroy pins and allow rotation.

Impressioning – Creating a working key by analyzing marks on a blank key inserted into the lock.

Force Attacks – Using prying tools or striking the lock to break it free.

To counter these threats, vending operators often combine plunger locks with other protective measures like security bars, reinforced doors, or alarm sensors.

A vending machine plunger lock is only as effective as its maintenance program. Dirt, corrosion, and mechanical wear can compromise performance. Here are essential tips:

Regular Lubrication – Use a graphite-based or dry lubricant to keep pins moving freely. Avoid oil-based lubricants that attract dirt.

Inspect for Damage – Check for scratches around the keyway, which may indicate tampering.

Replace Worn Keys – Bent or worn keys can misalign pins and damage the lock over time.

Weather Protection – For outdoor machines, use protective covers to shield the lock from rain and dust.

Periodic Rekeying – Change the key combination periodically to maintain security, especially if keys are lost or staff changes occur.

While electronic locks and smart access systems are gaining popularity, mechanical plunger locks remain highly relevant. Advances in material science and lock design continue to improve their resistance to attacks, making them a cost-effective solution for many operators.

Some companies are now offering hybrid locks — mechanical plunger locks with integrated electronic tracking. These systems record every opening event, providing both physical security and operational oversight.

The vending machine plunger lock may be small, but its role is anything but insignificant. As a first line of defense against theft and tampering, it safeguards both the machine’s contents and the operator’s investment.

Understanding how these locks work, their strengths, vulnerabilities, and proper maintenance practices can help operators extend their service life and maximize security. Whether you’re managing a fleet of vending machines or simply curious about the hidden mechanics of everyday devices, the plunger lock is a perfect example of practical engineering meeting real-world security demands.