Most vending machines you encounter — from soda dispensers at train stations to coffee kiosks in office lobbies — are secured by a single, small but ubiquitous component: the tubular lock. Quietly installed on thousands of machines around the world, these round locks have become the go-to solution for vending operators because they balance convenience, cost and an acceptable level of security for everyday retail environments.

But as more businesses rely on unattended points of sale, questions are resurfacing about whether tubular locks remain the best choice. Are they secure enough? What makes them different from more familiar pin-tumbler locks? And for operators managing dozens — or hundreds — of machines across multiple locations, how do they keep keys under control? A closer look at tubular locks reveals why they became widespread in the vending industry, what their strengths and limits are, and what operators can do to protect revenue and equipment as the vending landscape evolves.

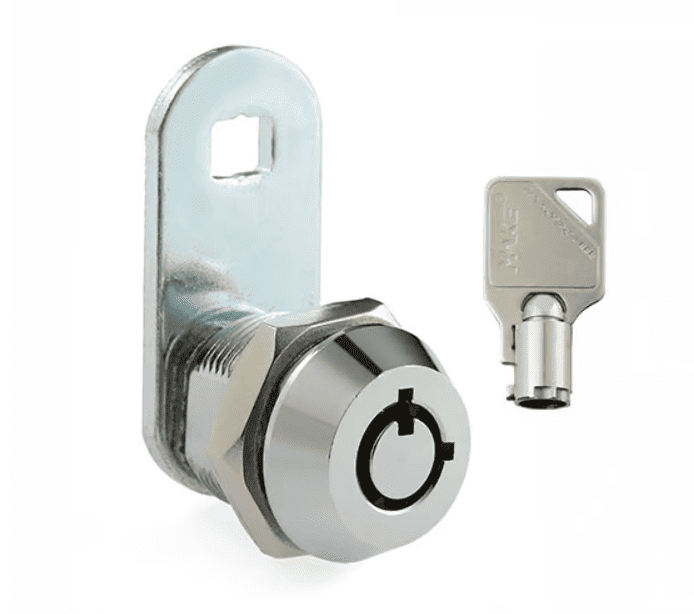

A tubular lock, sometimes called a radial or “Ace” lock, uses a round key and a circular keyway instead of the flat key and linear keyway common to household locks. Inside the cylinder, pins are arranged in a ring around the center; the key's notches depress those pins to the correct heights so the cylinder can turn. The distinctive look — a small circular hole and a matching cylindrical key — makes the lock easy to spot.

For vending-machine manufacturers and operators, tubular locks offer several practical benefits. They are compact, integrate neatly into thin metal doors and panels, and are relatively inexpensive. The circular key and keyway are less likely to snag in tight spaces, and the round key sometimes feels more durable in repeated use. Perhaps most importantly for fleets of machines, tubular locks lend themselves to master-keyed systems: one operator key can be configured to open many locks while individual keys still work for single machines. That simplicity of key management is a major reason operators have leaned on tubular locks for decades.

Imagine a vending business owner who services twenty machines across town. Carrying a unique key for every machine quickly becomes impractical; locking and unlocking multiple outlets would become a time-consuming, error-prone chore. Master-key systems solve that problem by creating a hierarchy of keys: individual keys open single locks, while a master key opens every lock in the system.

For small and medium-sized vending firms, a properly managed master-key arrangement reduces complexity. A service technician can carry a single master key, emergency access is simplified, and inventory of spare keys is easier to control. Many operators cite this operational advantage as the primary reason tubular locks have dominated the segment.

Tubular locks meet the security needs of many retail settings: they offer physical resistance to casual tampering and prevent opportunistic theft. However, security professionals caution against equating “sufficient for retail vending” with “high-security.” Like any widely used mechanical lock, tubular locks have known limitations.

Security analysts summarize the situation like this: tubular locks provide a reasonable deterrent against non-skilled attackers and prevent accidental openings. Against a motivated, informed intruder with specialized tools or knowledge, however, the locks can be vulnerable. This is not unique to tubular locks — many common mechanical locks share the same reality — but the specific geometry of tubular cylinders means vulnerabilities and exploit methods are well understood in locksmithing communities.

That said, vulnerabilities are a spectrum. A lock's susceptibility depends on factors such as manufacturing quality, the number of pins, whether it's been installed with additional reinforcement, and how well keys are controlled. Cheap or older tubular locks with fewer pins tend to be easier to defeat than modern, high-precision variants. Owners should treat tubular locks as one layer of security within a broader approach that includes solid cabinet design, surveillance, cashless payment options (so less cash is stored inside), and attentive service routines.

It's important to underline the legal and ethical landscape surrounding lock bypass techniques. Information about how locks can be defeated exists in many places, and locksmiths, security researchers and manufacturers study vulnerabilities to improve designs. However, attempting to open a machine that you do not own or have permission to service is unlawful in most jurisdictions. Vending operators worried about security should consult licensed locksmiths, security consultants, or the machine manufacturer — not try risky experimental fixes themselves.

Operators' concerns about tubular locks typically fall into two buckets: key management and unauthorized entry. Key management is a practical, logistical problem: losing a master key or allowing too many people to have copies increases the risk profile. Unauthorized entry — from attempted theft or vandalism — tends to be episodic but can be costly when it succeeds.

Anecdotal reports from the vending industry show that incidents range from petty theft of stored cash to tampering with product compartments. In many cases where machines were compromised, the root cause was not merely the lock type but weak key control practices: keys left in vehicles, untracked copies, or a failure to re-key machines after employee turnover.

Industry groups and security advisors therefore emphasize process: maintain minimal key duplication, log who has which keys, rotate keys or re-key locks after suspected compromise, and consider higher-security lock options when machines host large cash reserves or are sited in high-risk areas.

For vending operators seeking stronger protection than a basic tubular lock provides, several options exist:

• Higher-quality mechanical locks. Investing in tubular locks manufactured to tighter tolerances, with more pins and anti-tamper features, increases the effort required to defeat them. Some high-end cylinders include hardened cores and proprietary pin layouts.

• Electronic locks. Keyless entry systems using PIN codes, proximity cards, or mobile credentials eliminate physical key control issues. Electronic locks can offer audit trails, remote management and the ability to change access codes without re-keying hardware. They do, however, introduce new considerations: battery life, network security (if connected), and higher upfront cost.

• Integrated physical security. Reinforcing door edges, using tamper-evident screws, and enclosing cash boxes inside secondary locked compartments can reduce the payoff even if a lock is bypassed.

• Cashless and telemetry solutions. Many modern vending machines accept cashless payments and are connected to remote telemetry platforms that report inventory and cash levels in real time. Less physical cash in the machine is a powerful theft deterrent.

Choosing among these options depends on a machine's location, the value of the inventory and cash it holds, and a business's service model. For instance, a coffee vending machine in a busy corporate lobby may warrant higher investment in electronic access and cashless payments; a snack machine in a low-risk office might remain well-served by a quality tubular lock and sound key control.

Security experts recommend several common-sense practices tailored to vending operators:

Key control discipline. Limit the number of master keys, track who has them, record key issuance and return, and enforce strict rules for duplication. If a key is lost, re-key affected machines quickly.

Regular maintenance and inspection. Routine checks can identify signs of tampering early, reducing losses and preventing escalation.

Situational risk assessment. Evaluate each machine's location and adjust security accordingly. High-traffic or remote sites often need stronger protection.

Invest in design and placement. Position machines in well-lit, observable locations and mount them securely to reduce the likelihood of forced entry.

Adopt cashless payments where feasible. Reducing or removing cash lessens incentive for theft and can simplify accounting.

Partner with reputable locksmiths and suppliers. Work with trusted vendors who can recommend lock upgrades, electronic access options, and secure master-key setups.

As unattended retail evolves, vending machines are becoming smarter. Connected machines provide telemetry, remote diagnostics and dynamic pricing — and they create new options for access control. Fleet managers can provision access remotely, apply time-limited credentials to service personnel, and receive tamper alerts.

These capabilities change the calculus for locks. While mechanical locks will likely remain common for years — they are cheap, robust and familiar — many operators see hybrid approaches as the smart path forward: keep a mechanical lock for redundancy, and layer remote electronic control when the business case supports it.

At its core, the story of tubular locks in vending is a story about trade-offs. They are compact, cost-effective and well-suited to the logistical needs of businesses that must open many machines across multiple sites. Where high-security needs are low to moderate, they are a pragmatic choice. But they are not a silver bullet. The vending industry's challenge is to balance the convenience of master-key systems with controls that prevent unauthorized access.

Security is rarely about eliminating risk entirely; it's about managing it to an acceptable level. For vending operators, that means combining sensible mechanical protection with disciplined key management, situational awareness and — increasingly — electronic technologies that reduce reliance on physical keys.

Information about lock mechanics and vulnerabilities serves an important public purpose: it helps operators and manufacturers make machines safer. However, it is equally important to discourage misuse. Unlocking devices, bypass techniques and other detailed instructions that would enable unauthorized access should be discussed only in the context of professional locksmithing, security research, or with the explicit consent of the owner.

If you operate vending machines and have security concerns, the responsible route is to engage qualified locksmiths or security consultants. They can assess your fleet, recommend upgrades, implement master-key systems with strict controls, and install electronic access where appropriate. That way, the hardware that keeps your business running remains a help — not a liability.